|

Issues in Supply Chain Management |

Companies can enhance their SCM performance by focusing on the issues that influence SCM performance. It is found that SCM encompasses planning, manufacturing, and operations management necessary to bring a product to the marketplace, from the sourcing of materials to the delivery of the completed product. ERP is a computerized integrated set of application software modules for different business processes such as production, distribution, financial, human resources, procurement, supply chain management, etc., used by firms providing operational, managerial, and strategic information for making decisions strategically to improve the productivity, quality, and competitive advantage. EDI is an inter-organization computer-to-computer exchange of standard business documents in a structured and machine-processable format without human intervention to improve the speed and accuracy of the information flow. Information sharing practices such as vendor-managed inventory (VMI) give manufacturers access to more accurate demand information. VMI is an inventory control system in which a supplier/vendor monitors, manage and replenish inventory on a customer’s site with extensive use of latest information and communication technologies without generation of order by the later.

Information Technology and Information Management:

Sanchez and Perez (2003); Tarn (2002); Wieder (2006) examined functions, current developments, and the rationale for IT integration by analyzing the problems of enterprise resource planning (ERP), electronic data interchange (EDI) and presented the solutions of SCM.

Enterprise Resource Planning (ERP)

ERP is a computerized integrated set of application software modules for different business processes such as production, distribution, financial, human resources, procurement, supply chain management, etc., used by firms providing operational, managerial, and strategic information for making decisions strategically to improve the productivity, quality, and competitive advantage.

Electronic Data Interchange (EDI)

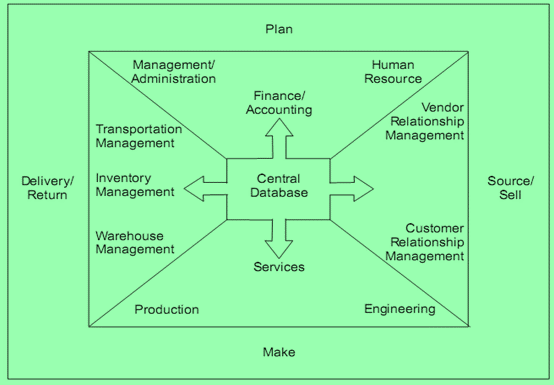

EDI is an inter-organization computer-to-computer exchange of standard business documents in a structured and machine-processable format without human intervention to improve the speed and accuracy of the information flow. ERP System Components are shown in Figure 1.

Figure 1. ERP System Components

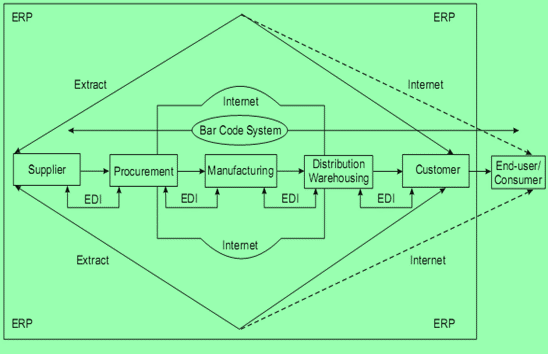

ERP Electronic Data Interchange (EDI) is shown in Figure 2.

Figure 2. ERP Electronic Data Interchange (EDI)

Vendor-managed inventory (VMI)

Information sharing practices such as vendor-managed inventory (VMI) give manufacturers access to more accurate demand information. Småros (2003) et al. [22] used discrete-event simulation to examine how a manufacturer can combine traditional order data available from non-VMI customers with sales data available from VMI customers in its production and inventory control and what impact this has on the manufacturer's operational efficiency. VMI is an inventory control system in which a supplier/vendor monitors, manage and replenish inventory on a customer’s site with extensive use of latest information and communication technologies without generation of order by the later.

Characteristics

- Multiple outlets

- Severe consequences in case of human errors

- Strong competition and small margins

- Lack of brand loyalty in case of stock-outs

- Steady growth and high volumes

- High inventory carrying costs and a high degree of demand unpredictability and uncertainty

Comprehensive framework for the successful implementation of VMI:

- Top management commitment

- Clarify expectations

- Data synchronization for information sharing

- Keep communication channels open

- Measurement

Knowledge Management:

Knowledge is critical for organizations to satisfy customer needs for customized products and services, and speedier and improved service (Davenport and Klahr, 1998)

Lang (2001) et.al. [15] Desouza (2003) et.al. [5] linked the impact of organizational structure in knowledge transfer and utilization among the different participating functions in the perspective of systems theory

Horwitch and Armacost (2002) and Alavi and Leidner (1999) defined knowledge management as the systematic and organizationally specified process of acquiring, organizing, and communicating knowledge so that employees can use it to become more effective and productive in their work.

Knowledge Management definitions are shown in the Table 1

Table 1: Knowledge Management definitions:

|

S. No.

|

Authors Year |

Knowledge Management definitions |

|

1 |

Grey (1996) |

KM is a collaborative and integrated approach to the creation, capture, organization, access and use of an enterprise intellectual asset. |

|

2 |

Bair (1997)

|

KM aims to capture the knowledge that employees really need in a central repository and filter out the surplus. Use of technology to capture the knowledge residing in the minds of the employees so that it can be easily shared across the enterprise |

|

3 |

O'Dell and Grayson (1998) |

KM is a conscience strategy for moving the right knowledge to the right people at the right time to assist sharing and enabling the information to be translated into action to improve the organizational performance. |

|

4 |

Lytras (2002)

|

The cumulative ability to utilize the value incorporated in the various stakeholders in of an organization. KM is the integration of knowledge assets in reusable formats that sets a win-win relation for all the parts of the knowledge Web. |

|

5 |

Information Week (2003) |

KM is the concept under which information is turned into actionable knowledge and made available effortlessly in a usable form to the people who can apply it. |

|

6 |

Kimiz and Dalkir (2005) |

KM is the deliberate and systematic coordination of an organization’s people, technology, processes, and organizational structure in order to add value through reuse and innovation. |

Customers - Supplier Relationship Issues:

Efficient consumer response (ECR) is a supply chain management strategy that attempts to address the inefficiencies in the supply chain. Hoffman and Mehra (2000); Harries (1999) Sparks and Wagner (2003) discussed efficient consumer response (ECR) as a supply chain strategy by analyzing the adoption of ECR strategy in some industries. Jonsson and Zineldin (2003) et. al.. [9] proposed conceptual model including behavioral dimensions of supplier-dealer relationships and presented hypotheses about how to achieve satisfactory inter-organizational relationships. Lambert and Pohlen (2001) et.al. [13, 14] provided a framework for developing supply chain metrics that translates performance into shareholder value.

Customer relations Issue:

A company's customer relations practices can affect its success in managing the supply base as well as its performance (Scott and Westbrook, 1991 et.al. [21]; Ellram, 1991 et.al. [6]; Turner, 1993). A key element of successful supply base management involves downstream integration of customers as well as the management of upstream suppliers.

Issue of Supply chain Design:

Braganza (2002) and Power (2005) et.al. [20] examined different perspectives on integration and suggested that integration of several functions at different organizational levels achieve above average financial and performance results. Manson- Jones (2000) et. al.. [16] demonstrated how the “lean" and “agile" paradigms might be integrated. They designed a total performance metric and developed a route map for integration of lean production and agile supply in the total chain. Lalwani (2006) et.al. [12] suggested that one of the reasons for this might be the difficulty of grasping the full dynamic complexity of the processes and systems encountered.

Logistics management:

Lummus (2001) et. al.. [51] examined the historical definitions of both terms and proposed a hierarchy for the relationship between logistics and supply chain management. Srivastava and Srivastava (2006) et. al.. [23] ; Meade and Sarkis (2002) et. al. [17] presented a framework to manage product returns in reverse logistics by focusing on product ownership data, average life cycle of products, past sales, forecasted demand and likely impact of environmental policy measures. Neves (2001) Ma and Davidrajuh (2005) proposed distribution channels planning model. Authors explored the use of an iterative approach for designing distribution chain in an agile virtual environment; and proved that quick adaptation to changing market situation and automation of supply chain management processes are essential.

Global Issues:

Jennings (2002) et.al. [8] and Zeng (2003) et.al. [25] projected strategic benefits and problems relating to the outsourcing decision. These include issues of cost, quality, flexibility, strategic focus, and diversification, the potential loss of critical skills and knowledge, and appropriation of final product value. Buxey (2005) et. al. [4] and Svensson (2001) et.al.[24] explored the linkage between firms' outsourcing activities and the occurrence of supply chain disruptions. Blowfield (2005) et.al. [3] discussed the experience of employing global social and environmental standards, in terms of a global ethic.

Partnership Issues:

Horvath (2001) proposed that Collaboration through intelligent e-business networks would provide the competitive edge to all the participants in a value chain to prevail and grow. Frankel (2002) et al. [7] showed that one of the most common usages of partnerships is in the provision of transport and distribution services.

Environmental issues:

Power (2005) et al. [20] presented a conceptual framework to investigate supplier relations, lean manufacturing, environmental management practices; and their relationship to one another

Trust and Commitment:

The two fundamentals’ components of improving the relationship are trust and commitment (De Ruyter 2001). The cooperation arises directly from both relationship trust and commitment (Morgan and Hunt 1994 et al. [19]). According to past research, trust has two dimensions: “honesty” and “benevolence” (Kumar. 1995) et al. [10, 11]. There are several dimensions of trust in fresh produce supply chain performance such as confidence in preferred trading partner, always keeps promises, always honest, good reputation, trust in preferred trading partner, believe information provided, close personal friendship, trading partner always consider best interests (Batt 2003). Trust is the belief that the partners will act in ways that will bring positive outcomes for the firms and does not want to take unexpected actions that may bring a negative outcome (Anderson and Narus 1990 et al. [2]). Trust (Moorman 1993 et al. [18])) is the willingness to rely on an exchange partner in whom one has confidence. Or trust as a belief, a sentiment or an expectation about an exchange partner and results from the partner’s expertise, reliability and intentionality. Trust is the extent to which the buyer believes that the supplier has the necessary expertise to perform the activity effectively and reliably (Ganeshan 1994)

Contemporary Issues and challenges in Supply Chain Management

- Minimizing Uncertainty

- Minimizing the Number of Linkages or Stages in the Network

- Improving Process Quality

- Minimizing Variety and Delaying Differentiation

- Reducing Replenishment Cycle Time

- Improving Flexibility

- Enhancing Demand Fulfillment Capability

- Competing on Service

Conclusions

Companies can therefore enhance their SCM performance by focusing on the issues that influence SCM performance. It is found that SCM encompasses planning, manufacturing, and operations management necessary to bring a product to the marketplace, from the sourcing of materials to the delivery of the completed product. The issues that are to be managed in supply chain such as Customers Supplier Relationship Issues, Global Issues, Knowledge management issue, Logistics management, Partnership Issues, Contemporary Issues, and challenges in Supply Chain Management are discussed in this paper. Knowledge management used as the systematic and organizationally specified process of acquiring, organizing, and communicating knowledge so that employees can use it to become more effective and productive in their work. Logistics management described for the relationship between logistics and supply chain management. Global Issues projected strategic benefits and problems relating to the outsourcing decision. These include issues of cost, quality, flexibility, strategic focus, and diversification, the potential loss of critical skills and knowledge, and appropriation of final product value. Partnership Issues would provide the competitive edge to all the participants in a value chain to prevail and grow. Contemporary Issues and challenges in Supply Chain Management Minimizing Uncertainty, Minimizing the Number of Linkages or Stages in the Network, Improving Process Quality, Minimizing Variety and Delaying Differentiation, Reducing Replenishment Cycle Time, Improving Flexibility, Enhancing Demand Fulfillment Capability, Competing on Service. A key element of successful supply base management involves downstream integration of customers as well as the management of upstream suppliers.

Source: ResearchGate.net

Related Articles

|

Who Is In Charge? You or the Child?Who is in charge of that challenging situation? Is it you or the child? In my past articles I have encouraged children to be given freedom of expression but when they push the boundaries consistently, who is in control? I quite understand the frustrations that adults face when they [Read more]

|

Posted: 12 years ago |

|

Gain Report - Nigeria: Sugar AnnualReport Highlights:

Nigeria depends almost exclusively on sugar imports in the form of brown sugar, largely imported from Brazil (98 percent) despite privatization of all government -owned sugar resources. The Nigerian sugar industry has been reinvigorated by privatization; however, production rem [Read more]

|

Posted: 15 years ago |

|

Accountability: Effective Managers go FirstAfter attending one of my seminars, Jay Bertram, president of the Toronto office of TBWA, the global advertising agency, returned to his office and immediately asked all his people to evaluate their overall job satisfaction, their feelings about the office and (most critically) their overall rating [Read more]

|

Posted: 16 years ago |